The era of electrified freight shipping has begun.

This article got me thinking. It's about the launch of the world's first kilotonne-class electric freight ship (ironically, a collier): 70,5 meters long, 13,9 meters wide, dual 160kW motors, and 2,4 MWh of batteries, to take 2000 tonnes of coal on a 50mi / 80km trip. As waterborne shipping is one of the largest global consumers of petroleum, this is a first step in something huge. But how close are we to being able to convert oceanic freight shipping?

Let's break down the numbers on this ship. A naive calculation would suggest:

- Motors: 2x176W/tonne = 352W/tonne

- Energy consumption: 24W/tonne-mi / 15Wh/tonne-km

- Battery mass @ 150Wh/kg (NMC): 0,16kg/tonne-mi / 0,10kg/tonne-km

- Battery mass @ 180Wh/kg (NCA): 0,13kg/tonne-mi / 0,083kg/tonne-km

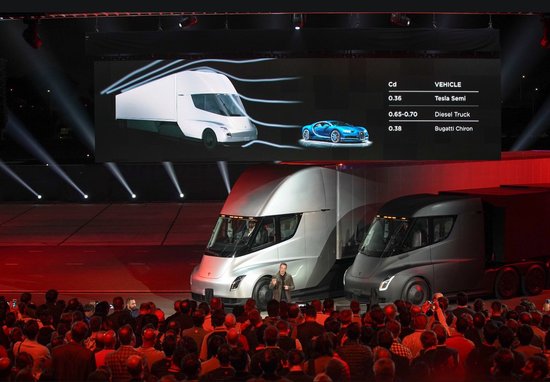

This would be a third the energy per tonne-mi as Tesla’s Semi (“under 1243Wh/km” with 36,3 tonnes GVW, assumed 10 tonnes for the tractor = 26,3 tonnes payload = under 47Wh/tonne-km) . But something's curious about this – as the difference between the ship and Tesla’s Semi should be even greater. According to Deutschebahn (well to wheels energy consumption):

- Air freight 2906Wh/tonne-km

- Road freight: 364Wh/tonne-km

- Rail freight: 97,2Wh/tonne-km

- Ocean freight: 30,5Wh/tonne-km

Now, a couple things immediately jump out from this.

1) They show road freight consuming an order of magnitude more energy than Semi

2) They show the difference between road and oceanfreight being 12-fold, not twofold.

What's going on? Well, a few things.

1) These are well-to-wheel figures. Semi is pack-to-wheel figures. Diesel costs about 20% of its contained energy to produce (https://hub.globalccsinstitute.com/publications/biofuels-policies-standards-and-technologies/petroleum-diesel-life-cycle-energy-demand). Fuel oil in ships is similar to diesel and the overhead is likely similar. The numbers then become:

Road freight: 303Wh/tonne-km

Rail freight: 81Wh/tonne-km

Ocean freight: 25,4Wh/tonne-km

(Omitting air freight because air travel is a whole new can of worms 😉 )

2) Electric motors are much more efficient than internal combustion engines. The larger the engine and the more it's allowed to run in an optimal power band, the more efficient the ICE. We'll assume that Semi, with its NMC batteries and PM drivetrain, gets a ~90% pack-to-wheels efficiency. A large truck's diesel engine may peak around 45%, but on average may run around 39% efficiency over the SET cycle. Train engines are larger and theoretically run closer to optimal, but lose some energy in electrical conversion; some sources say a typical modern efficiency is 36%. Large marine diesels can achieve over 50% efficiency, and one expects them to be able to run reasonably near maximum on average at cruising speeds; let's assume 50%. Thus, adjusting from diesel to electricity, we get the following:

Road freight: 133Wh/tonne-km

Rail freight: 32,4Wh/tonne-km

Ocean freight: 12,7Wh/tonne-km

3) Teslas Semi is not a normal freight truck. It's aggressively streamlined, and the tractor uses super single tires (they may be assuming super singles for the trailer as well). They may well be effectively halving the energy used by road freight; this would change the 133Wh/tonne-km figure to 65Wh/tonne-km.

This, however, still does not fully explain the difference (65 vs. “under 47” Wh/tonne-km). It's difficult to know how Deutschebahn calculates its figures and what other factors are affecting their average energy consumption (idling? partial loads? Empty return trips? Etc), to know how to adjust their ocean freight numbers. Let's just say that ocean freight should decrease to 10Wh/tonne-km to account for “other factors not heretofore considered”.

Does this sound reasonable? The Chinese collier achieved 15Wh/tonne-km, according to a naive calculation. However, a few factors play into this:

* This assumed that each trip uses 100% of the battery. Obviously there will be a buffer

* It's river travel, not oceanic

* The larger the ship, the greater the efficiency (as a general rule)

* If the ship itself gets heavier due to battery mass, its cargo will decrease, and the energy per unit cargo will increase.

So these numbers do indeed appear to roughly match up.

While the Chinese collier looks like a pretty traditional design (and may even be a retrofit into an existing hull), there are a number of modifications (http://gcaptain.com/part-design-efficient-ship/) that can be made (and probably would be made) on the large scale to improve ship efficiency (some quite significantly), as the extra expense for improved efficiency decreases the required battery mass (important on very long trips – not so much for an 80km collier); this is critical, as ship mass, not volume, determines the displaced area under the waterline, and thus drag. We've seen this time and time again when it comes to large-scale electrification – EV passenger cars are built lighter and more streamlined than ICE passenger cars, EV trucks are built lighter and more streamlined than traditional trucks, etc. Let's assume the ocean freight figure drops to 8,5Wh/tonne-km.

The distance from New York to London is 5585km. This is neither the shortest route, nor the longest, but ~5500km seems a reasonable length route for a ship which is range limited. On top of this, we must add a safety buffer – say, 6500km total range. We must now decide on our battery technology from the current two leading contenders – but that is easy. Battery packs on a transatlantic cargo ship would undergo very few cycles per year, as each journey takes weeks, so a higher energy density / shorter cycle life chemistry like NCA seems more appropriate. Thus we end up with 307kg-batteries/tonne cargo and 55kWh/tonne cargo (assuming the ship displacement / cargo mass ratio remains constant; otherwise, the batteries eat into cargo capacity).

A Maersk Triple E-class container ship has an empty displacement of 55 kT and a cargo (deadweight tonnage) of 165 kT, for a total of 220 tonnes. Let's assume that the base displacement of an EV equivalent, without the need for the engines and all support hardware, and built light (for obvious reasons) is 40 tonnes. We thus end up with 50,6 kT of batteries for a net empty displacement of 90,6 kT. This reduces the cargo to 74,4 kT, or 45% of its original capacity. This is obviously undesirable – although nonetheless potentially workable if the cost incentive for switching was great enough. Battery capacity would be 9,1 GWh. Current Semi batteries look to be around $80-85/kWh (after profit), from raw materials of around $50/kWh (spike prices). Assuming that production catches back up to the demand curve and prices continue to fall, let's assume $50/kWh; the battery pack thus becomes $455m. Given that an entire Maersk Triple E costs $185m at present, this is likely impossible to justify. The situation becomes all the worse when one considers Pacific routes, or other routes longer than the nominal 6500km maximum above. One could posit battery improvements – and some will certainly occur – but you not only need to improve energy density, but price simultaneously. That's a big ask.

There is, however, a workaround, as strange as it may sound: oceanic gigachargers, powered by floating wind turbines and/or floating solar.

Floating wind being tested in its first real-world deployments (with the first turbine going live in 2013). Floating solar is used in increasing amounts in sheltered freshwater environments, but only just starting to be experimented with at sea. While costs are currently high due to the immature state of deep sea power generation, there are significant advantages; for example, wind turbines benefit greatly from increased tower heights and rotor diameters, but sizes are limited on land due to the difficulty of transporting large tower segments on roads or rails. There are no practical size limits for the construction and transport of offshore structures. Likewise, floating solar is about 10% more efficient than solar on land, due to water cooling and reflections from the ocean. Regardless of the source, power would be buffered by large battery packs, which then surge-charge connected ships.

If we consider the case of visiting gigachargers at ~700km intervals along popular oceanic routes (with the gigachargers themselves spaced 2-3 times as close), the battery size reduces from 9 GWh to 1 GWh (an eminently affordable $50m at $50/kWh, or a worst case $100m at $100/kWh). Time between gigachargers is approximately 1 day. With 2 1/2 hours docking / charging / departure times, travel times increase by 10%. The empty displacement of the ship becomes actually reduced compared to its diesel equivalent, meaning more cargo – potentially offsetting the charging time in full from a throughput perspective.

Fast and efficient docking is not merely something to be enabled by automated charging systems; the change in powertrains itself helps enable it. Since the power source is already electric, it's a no-brainer to choose an azipod propulsion system. In such a design, many smaller propellers are mounted on azimuth mounts that can rotate in any direction tp propel the ship, rather than a small number of large, fixed aft rear screws directly connected to ICE powerplants. This not only decreases the required draft for the ship (aka, enabling it to visit shallower ports / waterways), but makes it amazingly maneuverable – even able to move sideways. Engine-out scenarios are also greatly reduced, due to the large number of azipods.

Some of the effects of switching from fuel oil are obvious. Commercial electricity – at least on the mainland in most places – is much cheaper than fuel oil. If offshore wind and/or solar matures properly, it should be able to provide the same benefit. Ports – normally places of terrible air pollution – suddenly become places of no air pollution. A large chunk of global CO2 emissions are eliminated.

Some of the effects, however, are less obvious. A key one to consider is that ports will have their own multi-gigawatt battery buffers, and at any given point in time, there will be a number of ~1GWh storage ships docked with them. This is a huge amount of storage connected to the local power grid, capable of buffering almost any grid fluctuations. In low-power scenarios, first, the rate of charge of the port battery can be reduced, all the way to zero, or even returning power in severe emergencies (of a degree worth the cost of delaying ship traffic). Since the ships go through so few charge cycles per year, using them for Vehicle-To-Grid (V2G) in emergencies does not present a wear concern. Indeed, in bad situations, additional ships could be routed to a struggling port (particularly ships which have no cargo on hand, and thus use significantly less power per kilometer), to offload power to the grid (whether from other ports or offshore superchargers). A ship like the above costs between several thousand and several tens of thousand per day in rental fees, but that works out to only around a cent or so of shipping fees (give or take an order of magnitude) per kWh imported. Lost some generation capacity from a hurricane? Had a nuclear power plant meltdown? In a power import dispute with a neighboring country? You don't need to sit in the dark.

The location of most of ships' energy coming from gigachargers out at sea means a displacement of the need to generate this power onshore. This means significantly reduced land usage for power generation, which in turn means more land available for natural and human uses, with no “NIMBY” opposition. It also solves a current problem with offshore wind and solar: how to get the power back to shore. Currently, further offshore a wind farm is, the more it costs to transfer the power back to the mainland, limiting the potential generation capacity and coming into NIMBY conflict wherein the generation hardware is visible from the shoreline. The entire cost of sea-to-shore power transfer can be eliminated from the power plants' budget.

As with the megachargers Tesla is building for Semi, you have to have a battery buffer for surge-charging vehicles; this would be no different with gigachargers. A key aspect often overlooked, however, is that you also need battery buffers (and/or peaking) with wind and solar power. The same battery buffer does double duty, both buffering charging and generation, and thus is a single line-item expense where normally you would have two. As in the case of Semi megachargers, the cost of the battery buffer is well less than the cost of the electricity generation hardware. Now, while megachargers have access to the grid to use as a peaking buffer in emergencies (or to sell excess power go), gigachargers would not. However, ships are not constrained to specific routes; if a patch of ocean is experiencing reduced generation (which would be experienced as higher prices at that gigacharger), less time-sensitive traffic will route through areas with higher generation / lower prices – with relatively minimal impact.

In short: conversion of freight shipping to electric power is not a “distant future, when 10x better / 10x cheaper batteries hit the market” scenario. It's doable in the surprisingly near term, as global battery production continues its exponential scaleup curve and floating wind / solar power generation matures. No new technology is required – just maturation and scaleup.

———-

Note: To head off the notion that invariably pops up: no, the world is not going to run out (insert-your-favourite-resource here). All of the components that go into modern li-ion batteries and electric motors (PM or induction) are available in abundance globally, while exploration and improved extraction technologies for them are only just now starting to get the attention that they deserve. And even the amount of the “rarer” components used in batteries (such as cobalt – although even that is not a “rare” substance) are declining, on a per-kWh basis.